UNSTABLE ROCK AND ITS TREATMENT SNOWY MOUNTAINS SCHEME

Comparison of steel ribs and rock bolts

Where steel ribs supports are required, the tunnel cross-section has to be made larger than the cross-section in unsupported rock. This is the case both in fully concrete lined tunnels and in unlined tunnels. In the fully concrete lined tunnels the finished internal diameter is kept constant throughout the length of the tunnel, the enlargement is required because the total thickness of steel ribs and timber blocking and the required thickness of concrete over the inside of the steel ribs is greater than the thickness of the concrete lining over unsupported rock. The parts of tunnels where steel rib supports are used, thus require additional rock excavation and additional concrete compared with the parts that are unsupported. Also an anomalous situation is created where the larger, and therefore less stable opening, is made in the inferior rock, However, where rock bolts are used, no enlargement of the tunnel cross-section for unsupported rock is required.

The size of the steel ribs and their spacing can be varied to suit the rock conditions. However each individual steel rib is set at right angles to the centre line of tunnel and extends symmetrically across the tunnel from the same level at each side (commonly the floor) to the crown, irrespective of the position and shape of the area of rock weakness. Only the timber blocking and lagging is adjusted to the local rock conditions.

Where the zone of weakness crosses the tunnel at about right angles the steel rib is fully utilized, However if the zone of weakness is nearly parallel to the tunnel and is narrow, only a small part of each steel rib is directly in contact with the unstable ground, the remainder being required only to provide structural continuity in the rib.

Rock bolts, on the other hand, can be limited to those areas of weak rock which require support.

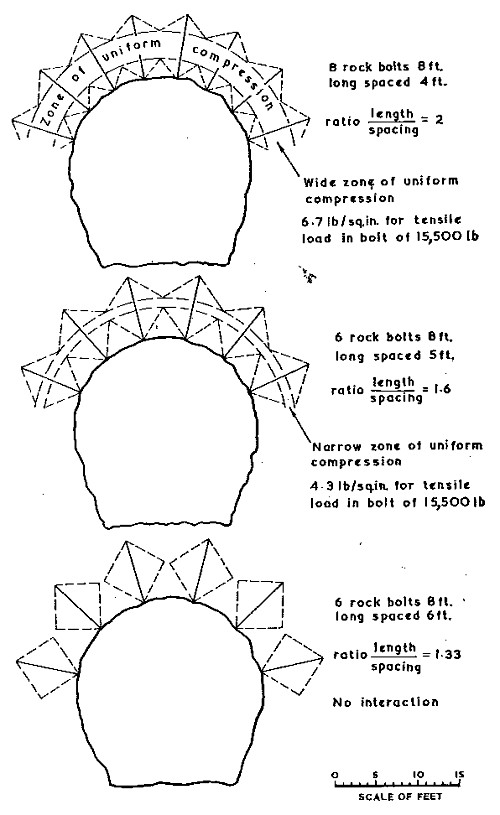

Fig 9.—Effect of variation of ratio spacing/length on patterns of rock bolts.

Final treatment

This is the treatment that the tunnel is given to ensure that there will be no significant rock falls or excessive erosion of weak seams while the tunnel is in service. Excavation by blasting followed by a long period of standing before the tunnel is placed in service is quite a severe test of the rock stability. However until it goes into service the rock is exposed only to air.